|Index|Profile|Story|New Products|

We believe that what is required of development in the future is ''the technical capability to maintain high standards of quality, low costs, rapid delivery times.'' Since the company was established, Bellco, Ltd. has maintained its position as a leading company in the sheet metal working industry. We have also facilitated and increased our volume production of resinous products. The company continues to advance in the sheet metal working industry based on our technical strengths and ability to work with various combinations of materials. We are committed to developing environmentally friendly materials and using recycled materials, while at the same time taking advantage of the best features of steel and aluminum materials to help our customers in new product development. We are poised to pursue any possibility in areas related to vehicle production, and bring ideas to reality. From the simple to the complex, each task receives our dedicated attention. We are ready to serve with made to order products.

|

|||||||||||||||||||||||||

| Bellco, founded in the spirit of sheet metal working | |||||||||||||||||||||||||

To respond to increasingly diverse customer needs Bellco carries out product development based on high-level engineering, but our starting point is always with sheet metal. What is required today for automotive product development, particularly on minor model changes, is the ability to translate a design image into reality and produce a 1:1 model prototype in a short period of time. This extends not only to the exterior, but often implies modifications that affect the car's interior. We believe that sheet metal work is the most cost-effective and rational approach to making such design changes with a short response time.----Sheet metal work is also an environmentally friendly approach. Why sheet metal makes possible low-cost and rapid response time: ・Body design changes are possible by working simply with cross-sectional profiles ・Clay models are not needed ・It is possible to consider interior design changes at the same time as exterior design changes (on the actual car model itself) ・Compared to other approaches it is easier to make changes

|

|||||||||||||||||||||||||

| Bellco Engineering | |||||||||||||||||||||||||

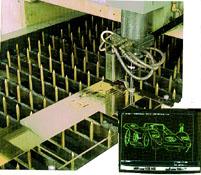

It takes special know-how to build a car. Even if you have expensive state-of-the-art manufacturing facilities, this alone is not enough to build a car. Bellco has earned its technical know-how in sheet metal work through direct experience in building race cars. Our starting point is engineering know-how. Bellco's engineering know-how is based on: CAD-based design (working with CAD drawings from the start) Technical know-how from building race cars (engineered design for durability, load, and strength, driving simulations, and reinforcement engineering know-how) Freedom of selection and design in matching different shapes (sheet metal, resinous materials, etc.) Can accept projects from the design level Capability to take measurements and data off of actual vehicles Thorough follow-up system Low-cost realized through comprehensive management |

|||||||||||||||||||||||||

| Specific example of sheet metal technology at work | |||||||||||||||||||||||||

1. Producing a section gauge (laser cut produces a section called a GABARI) 2. Making a panel Based on a section gauge, a panel is produced using roller handwork and welding. 3. Panel assembly The panel is positioned and attached, then Hemming-processed by folding over cut edges. 4. Finishing The finishing touches are completed with a minimal application of puddy. |

|||||||||||||||||||||||||